Sixth Wave Innovations (SIXW.C) announced that they have completed the initial Design for Manufacturing (DFM) of their Affinity System.

They also announced that they commissioned the delivery of the first system to Advanced Extraction Systems Inc. (AESI) in Charlottetown, PEI, and has given AESI approval of the design and bill of materials.

The Affinity system is Sixth Wave’s signature cannabinoid purification, isolation and anatomy control system. The system uses Molecularly Imprinted Polymer (MIP) technology to mimic nature. The Affinity system allows the user to selectively extract or absorb the compounds you are after into a polymer, even if the material the extraction is being performed on is very crude.

Because it’s a closed-loop system, even if everything you are after isn’t extracted, you can always run it for extraction again, as you never lose material. The system is also manufactured in a modular fashion, allowing for easy, rapid assembly and scale-up. Sixth Wave also intends to add additional modules if the company identifies further needs.

“We are pleased with the pace of design, development, and build effort that AESI is providing. We are achieving our expected milestones on schedule allowing us time to optimise the final product prior to customer delivery,” notes John Cowan Chief Operating Officer of Sixth Wave. “In addition, product design has been heavily influenced by AESI’s past experience with primary extraction equipment which will reduce risk and ensure a smooth production scale up to meet anticipated customer demand.”

The DFM includes an automated control center for programming and process control and metered pumps to deliver specific amounts of process fluid coupled with pressure sensors and tank fluid level sensors to ensure smooth process control without pulsing. It also includes mixing tanks which are automatically controlled & maintained to ensure process fluid effectiveness. These features allow for precise control of the process.

The design also includes valving that enables multi-direction process fluid delivery & retrieval options, column design that maximizes mass transfer zone & affinity bead efficiency, and full counter-current flow operation for the loading process enabled with an ancillary manifold to ensure 100% cannabinoid capture. These features ensure, as I noted earlier, that you don’t lose any material, allowing the user to maximize efficiency.

Finally, the modular nature of the design and the clean-out and sampling ports make the Affinity System easy to use and maintain. The whole system meets regulatory and industry build and safety requirements.

Sixth Wave says they remain on track to deliver the first three Affinity systems to AESI by the fourth quarter of this year.

“AESI is a well-established supplier in the cannabis space which provides us with the opportunity to leverage AESI’s current infrastructure to manufacture, service, and support production of Affinity units across North America. The management and engineering team at AESI continue to collaborate and invest in growth to support Sixth Wave.”

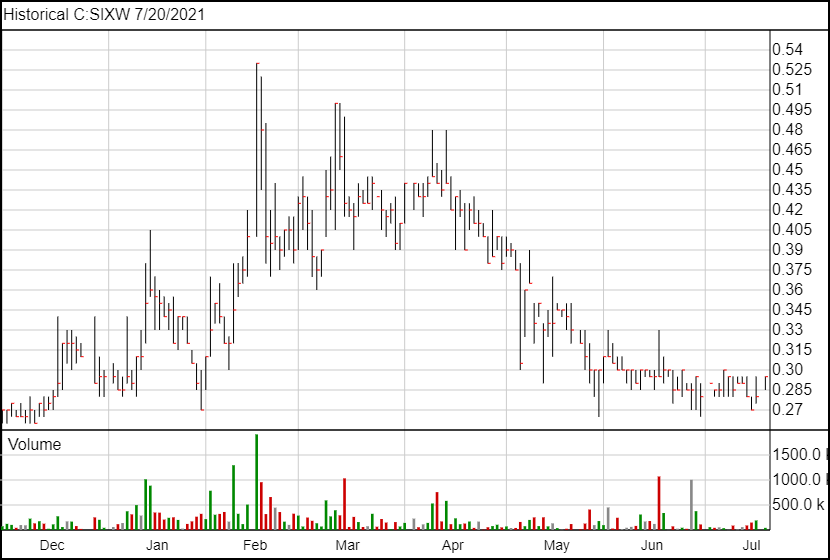

Following the news, Sixth Wave shares are up 1 cent and are currently trading at $0.29.

Full disclosure: Sixth Wave Innovations is an Equity Guru marketing client.