Our favorite uranium-vanadium company released metallurgical test results from their Ivana deposit last week.

Before we get to the news, a little background on Blue Sky Uranium (BSK.V):

We’ve looked at every aspect of Blue Sky, and we like what we see.

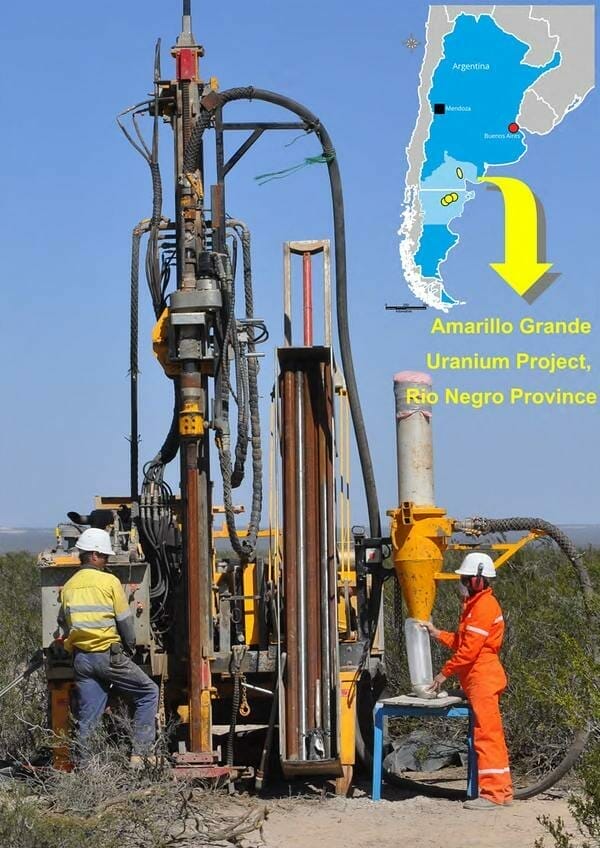

Blue Sky’s flagship project, Amarillo Grande, is located in central Rio Negro province, in the Patagonia region of southern Argentina.

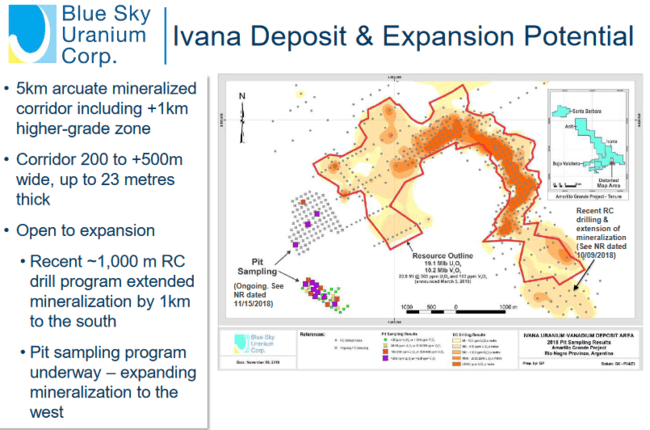

The mineralized footprint at Amarillo Grande is epic in scale – a 145 kilometer trend with three distinct mineralized zones.

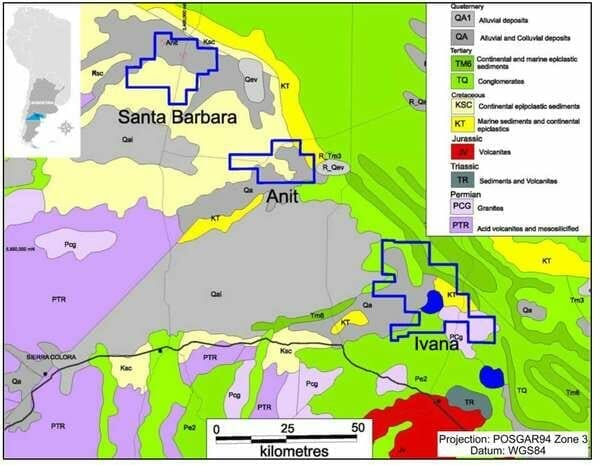

Note the scale on this map. We’re looking at kilometers, not meters.

The Ivana deposit seen on the lower right of this map currently sports a resource of 19.1 million pounds of uranium oxide and 10.2 million pounds of vanadium oxide. This represents the largest uranium discovery in Argentina over the past half-century.

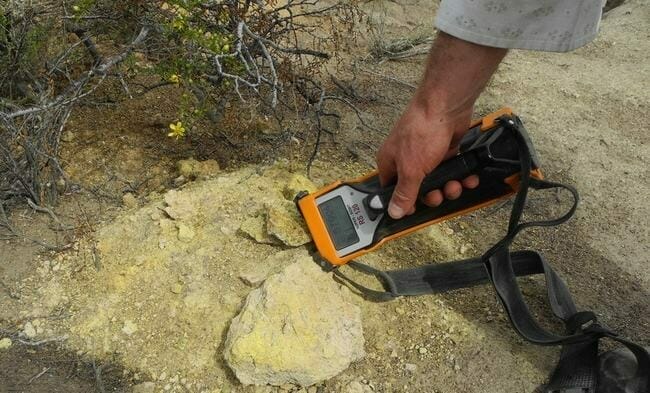

It’s the geological settings that the mineralization is hosted in that we find most exciting.

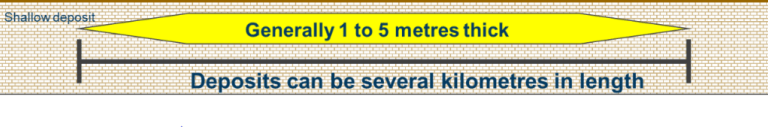

The bulk of the resource is surficial in nature.

It sits at, or just below, the surface in loose and poorly consolidated sediments. The valuable uranium and vanadium isn’t locked into the surrounding rock.

Mining this material will be a relatively simple process, e.g., no drilling or blasting required.

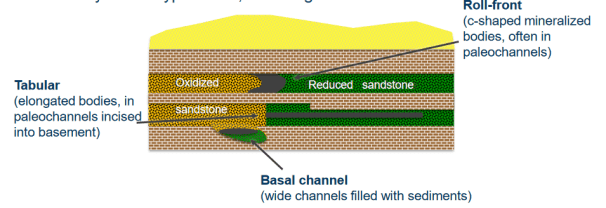

Ivana is also hosted in sandstone.

Though close the surface, the sandstone mineralization has the potential to run at depth.

Bottom line: Ivana’s 19.1 million pounds of uranium and 10.2 million pounds of vanadium lie right at surface in a setting conducive to easy extraction and processing, and there’s considerable potential to expand this resource.

Uranium, Vanadium, PEA studies…

When you think about mining operations, the first things that come to mind are massive open pits or deep shafts burrowed into the landscape, hoists, crushers, waste dumps, explosions, and 2 1/2 story high haul-trucks orbiting the chaos.

Extracting ore at Ivana will more resemble harvest-time on the family farm…

For a closer look at Ivana and all things Argentina, uranium, and vanadium, the following Equity.Guru offering should quench your thirst for greater detail…

Read: Blue Sky Uranium (BSK.V) tags high-grade uranium and vanadium values at Amarillo Grande

The Feb. 7th news…

The Company is pushing Ivana to the preliminary economic assessment (PEA) stage. The results are expected in the first quarter of the year.

A PEA is a first pass economic study that probes all the basic parts of a mineral deposit – resource, scale, logistics, etc. At this stage, an inferred resource is sufficient to get the ball rolling.

Metallurgical test results, like those reported in this press release, are an important component of the PEA.

The company is pulling out all the stops to get this work done right:

Under the guidance of the Company’s Technical Advisor, Chuck Edwards, P.Eng., several representative composite samples of uranium-vanadium mineralized material from the Ivana deposit were prepared and submitted to The Saskatchewan Research Council (SRC) for mineralogical, metallurgical and process engineering test work. SRC is one of Canada’s leading providers of applied research, development & demonstration, and technology commercialization, including specific expertise in uranium. SRC is an ISO 9001:2015 certified company.

The company’s process design flowsheet is based on a simple and low-cost, two-stage process.

Highlights include…

- Simple two-stage process of concentration/beneficiation followed by Alkaline Leaching using low environmental impact technology and reagents.

- Stage 1 – approximately fourfold increase in the grades of uranium and vanadium, and recoveries of 89% for both elements from simple wet scrubbing and screening of raw mineralized material to produce a Leach Feed Concentrate with an approximately 77% mass reduction.

- Stage 2 – recoveries of 95% for uranium and 60% for vanadium for Alkaline Leaching of Leach Feed Concentrate.

- The optimized leaching process requires no added oxidants and no flotation.

- Overall process recovery of 85% for uranium and 53% for vanadium.

The “simple wet scrubbing and screening of raw mineralized material” highlighted above can be performed on-site.

The combined free minus 100 µm mineral grains and the minus 100 µm mineral grains scrubbed from the coarse particles in the leach feed preparation process constitute approximately on average 23 weight % of the original raw mineralized material that comprised the representative composite.

In a mining scenario, this fourfold ability to concentrate the pay metals on-site dramatically reduces the amount of waste rock that would otherwise require transport.

This creates a beautiful processional effect which reduces the number of trucks required to haul ore, which in turn reduces labor costs, fuel costs, etc.

At SRC, Blue Sky Uranium’s leach feed preparation process development tests to date have consisted of 20 separate sets of scrubbing and screening tests. A first screening was done at 100 µm to separate the coarse and fine particles. A second screening was then done at 600 µm to separate the coarse material into more coarse and less coarse fractions in order to optimize the scrubbing of each coarse fraction. The aim of these tests was to demonstrate that raw mineralized material can be effectively concentrated, retaining as much of the uranium and vanadium as possible and reducing the mass of Leach Feed Concentrate and thereby contributing to lower operating and capital costs for alkaline leaching. These tests have shown that operationally proven and simple wet screening and scrubbing procedures result in an average 89% recovery for each of uranium and vanadium.

The tests:

The company also performed a leach feed flotation test to check for sulphide minerals, like pyrite (FeS2), which can negatively impact leach performance.

The test detected negligible sulphide flotation which further simplifies the process design.

During the alkaline leach testing phase it was determined that temperature is a key factor.

Optimal leach conditions are:

- 95°C.

- a carbonate/bicarbonate ratio of 60/10.

- a leach duration of eight hours with no oxident.

Optimized leach recoveries are 95% for uranium and 60% for vanadium. In addition, reagent consumption is low with Na2CO3 = 3.2 kg/t and NaHCO3 = 6.6 kg/t.

As mentioned above, the process design is made simple by the observation that neither the introduction of oxygen or flotation of sulphides are required to improve leach recoveries.

Cool beans!

The loaded solution resulting from leaching will be further processed to generate two separate products, a uranium oxide product (either UO3 or U3O8) and a vanadium product V2O5. The uranium oxide product will meet ASTM C967-13 Standard Specifications for Uranium Ore Concentrate.

The wet scrubbing and screening Leach Feed Concentration and Alkaline Leaching process design contemplated for the Ivana deposit incorporates proven and low environmental impact technology and reagents, such as sodium carbonate (Na2CO3) /bicarbonate (NaHCO3) leaching reagents. It also incorporates the capture and sequestration of radium as part of the process design.

Nikolaos Cacos, Blue Sky president & CEO on these met test results…

“These results indicate that Ivana mineralization can be processed using proven, simple and relatively inexpensive methods to achieve superior recoveries for both uranium and vanadium, which will make a significant contribution towards a very positive economic outlook for the project.“

Authors note: I’ve got a good feeling about this pending PEA.

A quick word on uranium and vanadium:

The Government of Argentina has committed to a 15% reduction in CO2 emissions by 2030. With three nuclear power plants in operation, one currently under construction, and two more on the drawing board, the country’s uranium consumption is set to more than double by 2025.

The country has no domestic source of yellow cake. You gotta know they want one in the worst way.

Vanadium flow batteries are on the verge of revolutionizing modern electricity grids. Uses and demand are increasing even though 85% of production comes from only three countries, and it’s heavily levered to iron ore production.

Final thoughts:

There’s likely far more to the Amarillo Grande story.

Blue Sky may be sitting on what may well turn into an entire uranium-vanadium district.

Look for the company to zero in on potential new discoveries over the next six to eight months. They have a number of high priority targets just begging for a proper poke with the drill bit.

In the meantime, the company continues to de-risk Ivana. We have a PEA on deck, slated for release this quarter.

The company has 109.79 million shares outstanding giving it an extremely modest market cap of $15.37M, based on its recent $0.14 close.

END

~ ~ Dirk Diggler.

Full disclosure: Blue Sky Uranium is an Equity.Guru marketing client.