In a recent offering, we suggested that Defense Metals is advancing its 1,708-hectare Wicheeda Rare Earth Element (REE) Project at a pace that should begin attracting a much wider audience.

The momentum continues to build.

Last week, the company dropped final bench-scale hydrometallurgical test results for Wicheeda:

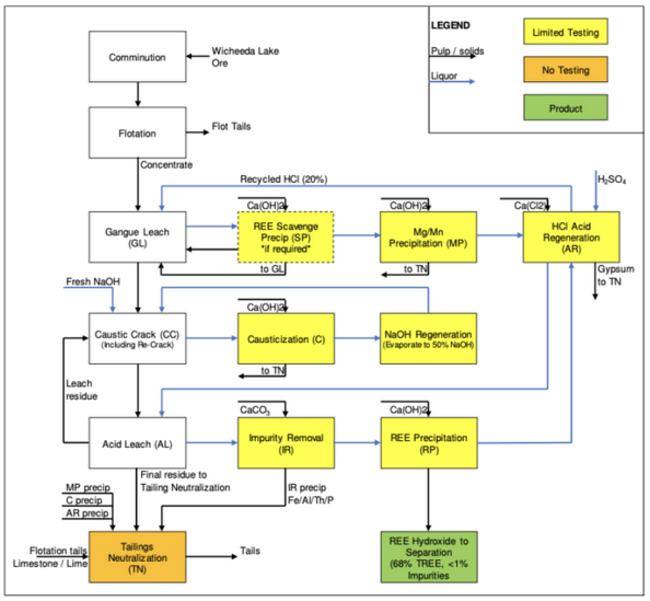

This was a constructive and satisfactory outcome—samples of flotation concentrate were used in a hydrometallurgical test that led to the successful development of a flowsheet capable of producing a mixed REE hydroxide precipitate.

The overall hydrometallurgical flowsheet is chloride based and uses hydrochloric acid to dissolve gangue minerals away from the REE carrying minerals. The REE containing leach residue is subsequently processed in a caustic treatment step to convert REE phosphates and fluorides into acid soluble REE hydroxides. The REE hydroxides are leached in hydrochloric acid and the leach solution is treated to remove impurities such as iron, aluminium, phosphorous and thorium. A purified and mixed REE product suitable for further REE separation can be produced either by hydroxide or oxalate precipitation. Final filtrates from gangue leaching and REE precipitation are combined and reacted with sulphuric acid to produce 20% (w/w) hydrochloric acid for re-use.

Craig Taylor, CEO of Defense Metals:

“These hydrometallurgical test results which showed REE extractions of ~90% from flotation concentrate, in conjunction with our recently released locked cycle flotation tests that produced a high grade 48.7% TREO concentrate, conclude a very successful yearlong metallurgical flowsheet optimization process. Defense Metals believes these are exceptional results that show the Wicheeda REE Deposit mineralization is readily amenable to processing via well-established flotation, and hydrochloric acid leach / caustic crack REE extraction methods. Based on these positive results we expect to finalize our plans to commence continuous pilot plant testing in the near future.”

“… readily amenable to processing via well-established flotation, and hydrochloric acid leach / caustic crack REE extraction methods” is music to an REE Developer’s ears.

REE (Rare Earth Element) deposits aren’t exactly rare, but finding one with sufficient scale and the right metallurgy is.

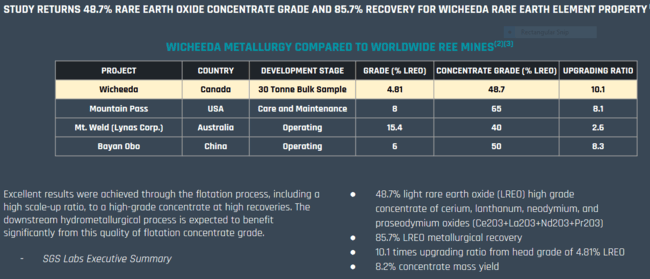

Previous metallurgical test results exceeded the company’s expectations elevating the Wicheeda deposit to among the very best in the world.

Initially, the company was shooting for the moon, targeting a total rare earth oxide (TREO) metallurgical recovery rate of 80%, and a TREO high-grade concentrate of 40%.

What they achieved from this earlier round of testing was nothing short of sensational:

- a TREO metallurgical recovery rate of 85.7%;

- a TREO high-grade concentrate of 48.7% TREO (cerium, lanthanum neodymium, and praseodymium oxides (Ce2O3+La2O3+Nd2O3+ Pr2O3))

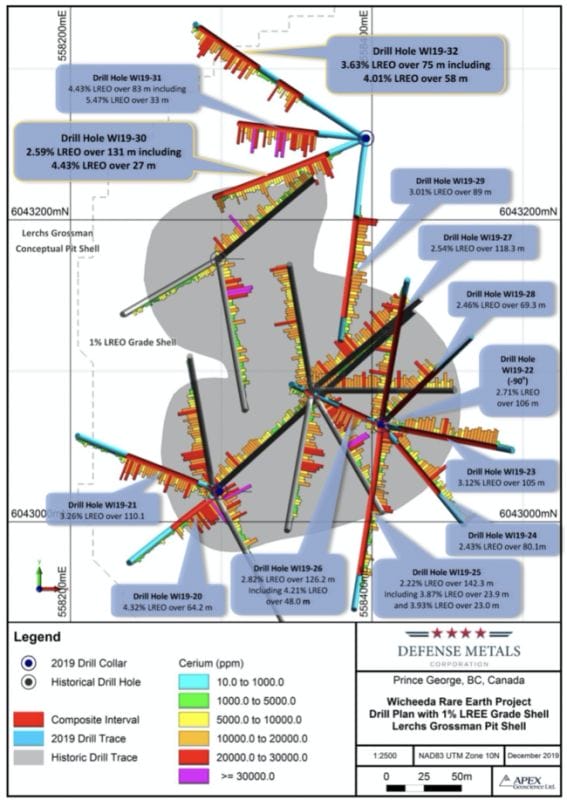

On the subject of scale, a recently concluded drilling campaign on the property expanded the Wicheeda deposit in multiple directions where it’s still open to the North, to the Southwest, to the East, and at depth.

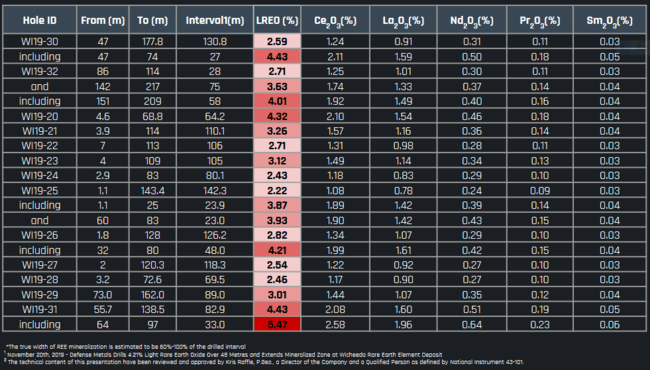

Note the drill hole intervals on the above map. Note the mineralization tagged beyond the previously defined boundaries of the deposit itself (Wicheeda’s current resource stands at 11,370,000 tonnes averaging 1.96% LREEs).

Here’s a better look at those assays:

Now consider that a grade of 1% LREE is equal to roughly 2.5 grams per tonne gold. To say that Defense’s current market cap of $8.14M is undervalued might be lowballing matters somewhat.

Back to Metallurgy

Scaling up the extraction/concentration process and building on momentum is par for the course with this crew, and to that end, the company dropped the following headline after yesterdays close:

This is an important, confidence inspired step—moving forward with a larger-scale pilot plant to process the remaining material from the 30-tonne bulk sample is a significant push along the development curve.

The objectives of pilot plant testing are to:

- Confirm metallurgy in a pilot plant environment;

- Generate data to support engineering;

- Produce a large amount of concentrate for downstream hydrometallurgy testing.

CEO Craig Taylor again:

“With the decision to move forward with the flotation pilot plant, Defense Metals has achieved another key milestone towards advancement of the Wicheeda REE Project. Since announcing the option agreement to acquire the Wicheeda REE Project 14 months ago we have collected a 30 tonne bulk sample; produced a maiden mineral resource estimate; completed a highly successful 13 hole, 2,005 metre diamond drill program; and successfully developed a combined flotation and hydrometallurgical processing flowsheet for Wicheeda REE mineralization. This has allowed Defense Metals to exceed its Year 1 and Year 2 exploration spend commitments within the first 12 months.”

As noted further up the page, Wicheeda’s current resource stands at 11,370,000 tonnes averaging 1.96% LREEs. But with the above-noted assays factored into a pending resource update, we could see a significant improvement in both grade and scale.

We shouldn’t have long to wait for that news to drop.

Looking at Defense’s price chart, the stock has had a nice run since the late October lows…

… but the valuation still seems a bit out of wack.

On deck is the resource update for the Wicheeda deposit.

We stand to watch.

END

—Greg Nolan

Full disclosure: Defense Metals is an Equity Guru marketing client.