As the global society continues to transition towards green energy, magnesium stands out as a critical mineral that will play a pivotal role in this shift. This lightweight, yet sturdy, mineral possesses numerous properties that make it ideal for use in various applications, particularly in green technologies. As environmental restrictions tighten and production costs in China rise, the potential for magnesium development outside China, particularly in North America, is increasing. Amidst this unfolding situation, Canada appears poised to become a key player in the international magnesium market.

Magnesium: A Mineral for Green Energy Transition

Magnesium is uniquely positioned with many advantageous properties. Being 33% lighter than aluminum and 75% lighter than steel, magnesium has carved out its unique place in a range of applications. Pure magnesium, although burns vigorously once molten, has higher melting points when alloyed. It is the third most used metal in construction after iron and aluminum, with about 70% of global production utilized in making alloys that are widely used in automotive and aircraft industries due to their low density, high strength, and excellent machinability.

These alloys are commonly composed of one or more elements such as aluminum, zinc, manganese, or silicon, dictated by the alloy’s intended processing. Around half of these magnesium alloys are employed in the production of die castings, with an average magnesium content of around 90%. High-pressure die-cast magnesium alloys are used in car components like steering wheel cores, gearbox casings, dashboard structures, and radiator supports.

To enhance the strength of these alloys, elements like zirconium and rare earth elements are introduced. Some of these alloys are even sand-cast into components for helicopters and jet engines, or used in the construction of high-performance cars and camera casings.

Magnesium also plays an indispensable role in the aluminum industry, acting as an alloying additive. These alloys are extensively used in packaging, especially in beverage cans and foils for food protection. It’s worth noting that most beverage cans in the US are made from aluminum alloyed with about 5% magnesium and a small amount of other elements.

Moreover, magnesium alloys serve as sacrificial anodes in the prevention of corrosion for steel ships, oil platforms, and pipelines. Magnesium, being more reactive, corrodes preferentially when connected to a less reactive metal, protecting the latter from corrosion.

Magnesium’s role isn’t limited to alloys. Around 10% of its global production is used in manufacturing titanium, and another 10% finds its use in creating high-grade steel for large buildings and bridges. Magnesium is also used in distress flares, fireworks, and other incendiary devices due to its ability to ignite.

Data from the U.S. Geological Survey’s Mineral Commodity Summaries, 2016, reveals that primary global magnesium production stands at 910,000 tonnes, with China producing nearly 90% of it. Over the last couple of decades, China’s rapid economic growth has led to increased demand for products using magnesium alloys, causing a shutdown of plants in many countries due to high energy consumption in the manufacturing processes.

In the age of dematerialization and the push for a circular economy, magnesium presents a unique opportunity. With the increasing demand for renewable energy sources, a decrease in the cost and carbon emissions of electricity, and the introduction of policies making it more costly to emit carbon dioxide, the game is changing for magnesium producers. The shift away from carbon-intensive production processes toward decarbonizable methods has become not only technologically feasible but also economically advantageous.

Electrochemical magnesium production, which utilizes seawater and inherently emits less carbon, is becoming increasingly attractive. The sheer potential of this method has even motivated traditionally labor-intensive and environmentally heavy producers like China to redirect their operations. A plant utilizing electrochemical technology to produce magnesium from brine has recently been commissioned, reflecting this shift. This move toward electrochemical technology positions magnesium production as one of the most economically competitive pathways to lightweight metal globally.

Unlike primary aluminum or steel production, which rely heavily on carbon for oxygen removal and are accountable for a substantial portion of global carbon dioxide emissions, magnesium offers a more sustainable alternative. The production process for magnesium has been achieving results without direct carbon dioxide emissions for over a century. This is largely due to the lack of oxygen in magnesium salts and the fact that magnesium electrolysis operates at significantly lower temperatures, hence consuming less energy compared to aluminum electrolysis and steel production.

Further highlighting its sustainable credentials, primary magnesium production can potentially become one of the cleanest in the world in terms of extractive metallurgy. The environmental advantages of magnesium extend beyond production into the end of its lifecycle as well. When magnesium corrodes, it transforms into magnesium hydroxide and eventually returns to the ocean as a soluble bicarbonate, effectively sequestering carbon dioxide in the process. Moreover, it can be reproduced from seawater without releasing carbon dioxide back into the atmosphere, making magnesium an inherently circular structural metal.

In contrast, aluminum and steel have linear value chains, always requiring solid mineral natural resources inputs and constantly producing waste that does not sequester carbon dioxide or reintegrate into the ecosystem. While all metals can be recycled, none can be recycled infinitely. Metal is always lost to dross or slag with each recycling cycle. For example, aluminum can only be recycled an average of 10-15 times before it is lost to waste. Magnesium’s sustainable lifecycle and potential for low-carbon production position it uniquely in the age of dematerialization and the transition towards a more circular economy.

Canada’s Role in the International Magnesium Market

Canada is solidifying its position on the global stage as a significant player in the magnesium production sector. Currently ranking as the third largest producer of primary magnesium, the country is expected to ascend to second place once a new production facility becomes fully operational. This projected rise is largely due to Canada’s abundant mineral resources and strategic investments in the magnesium industry.

Recognizing the environmental implications associated with magnesium production, the Canadian government, magnesium producers, and other stakeholders have undertaken joint initiatives to manage and mitigate the greenhouse gas (GHG) emissions resulting from production processes. These efforts include substituting sulfur hexafluoride (SF6) with more environmentally friendly alternatives, providing comprehensive training, and investing in public education on sustainable practices within the magnesium industry. The proactive measures are expected to make a significant contribution to meeting Canada’s commitments under the Kyoto Protocol.

Canada’s robust environmental regulations provide an added advantage in the magnesium sector, paving the way for more sustainable and environmentally conscious production methods compared to regions with less stringent environmental standards.

As the global magnesium market continues to grow – it was valued at USD 4.37 billion in 2021 and is projected to reach USD 6.36 billion by 2028, experiencing a compound annual growth rate (CAGR) of 5.50% – the demand for magnesium for traditional uses and novel applications, such as magnesium batteries and bioresorbable stents, is on the rise. Given this burgeoning demand and Canada’s proactive approach to environmentally friendly production, the country’s magnesium sector is primed for continued expansion and success in the global market.

A Canadian Magnesium Junior

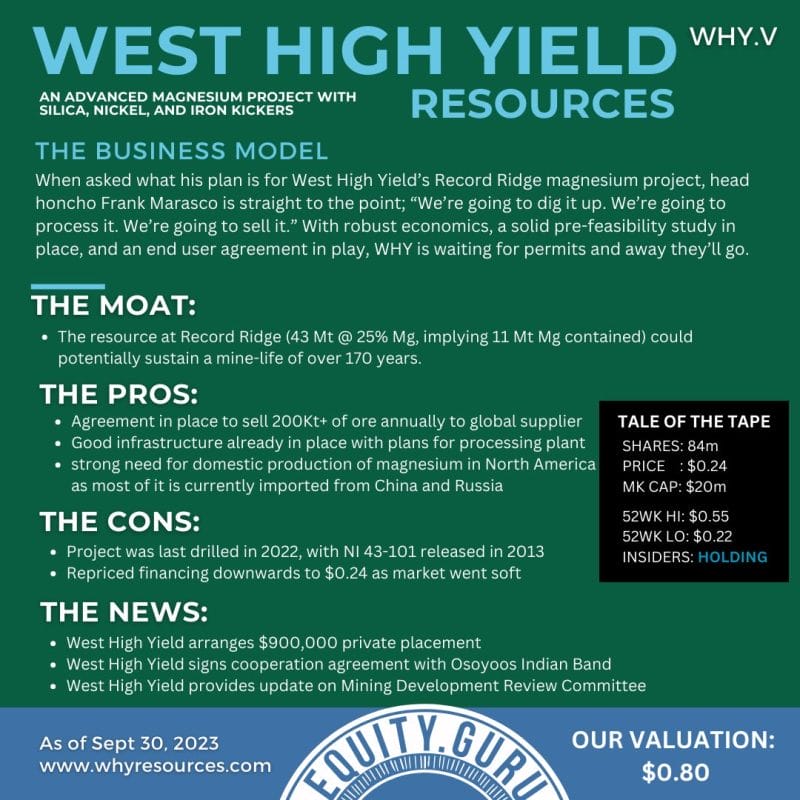

West High Yield Resources (WHY.V) is a publicly traded junior mining exploration company founded in 2003 and headquartered in Calgary, Alberta. The company is listed on the TSX Venture Exchange and its primary focus is the acquisition, exploration, and development of mineral properties in Canada. WHY’s flagship project is the Record Ridge South Magnesium Property, located just over 10 km west of the city of Rossland in British Columbia, and approximately 5 km north of the US-Canada border. This property, for which the company retains 100% of the mineral rights, has seen significant developments over recent years.

In 2013, West High Yield Resources released its Preliminary Economic Assessment (PEA) on the Record Ridge South Magnesium Project. The PEA detailed the potential economic viability and profitability of the magnesium mine, highlighting the rich magnesium deposits in two of the mineral claims.

As of 2023, the company made significant strides in its exploration and mining efforts. It completed comprehensive geotechnical investigations and submitted required information to the Ministry in response to requests for additional data. The company also made technological advancements through collaborations with companies such as KPM, KON Chemical Solutions, Tenova, and Bumigeme Inc., to carry out feasibility studies for the extraction of magnesium from the Record Ridge serpentine. The results validated the proposed chemistry and process conditions, promising the production of high-purity MgO and other valuable by-products.

West High Yield Resources also progressed its Midnight Gold Claim project, indicating high gold values from drilling operations initiated in 2022. Moreover, the company fortified its position through a strategic partnership with Big Blue Technologies LLC, aimed at constructing an Mg processing facility in Canada.

Recently, West High Yield Resources announced the closing of a sixth tranche under a drawdown equity financing facility with Alumina Partners, raising more funds to further its prefeasibility study Stage 3. These funds will also be used to prepare for mining of the magnesium ore in 2023 at its Record Ridge magnesium deposit.

The company’s CEO, Frank Marasco Jr., explains the potential of magnesium and the Record Ridge Project in his conversation with Chris Parry, the founder of Equity Guru. He also delves into his history of building and selling businesses, showing his confidence and experience in the industry.

With 20 years in the magnesium game, Marasco is no stranger to patience. Despite the high thresholds for mining in British Columbia and the lengthy process of getting permits, Marasco has been relentless in moving the ball forward. This determination is reflected in the company’s stock price that has held up for nearly two decades, even as they are on the cusp of entering the permitting process.

After a 20-year journey filled with exploration, raising funds, and technological advancements, it seems that the momentum is building for West High Yield Resources. Given the promising economics of the project, the emerging potential of magnesium, and the recent surge in investor interest, it is safe to say that the company is on the brink of entering an exciting new phase. The company and its stakeholders are eagerly anticipating the Ministry’s permit to expedite mine site development and kickstart the mining operations.

On May 29th, 2023, West High Yield Resources traded at $0.34 CAD per share for a market cap of $28.6 million.

Conclusion

As the world grapples with climate change and seeks sustainable solutions, the transition to green energy has never been more urgent. Magnesium, with its various benefits and wide range of applications, has the potential to be a vital player in this transition. As China, the current market leader, steps back due to environmental concerns, it presents a golden opportunity for countries like Canada to step up and lead the way in the magnesium market. By harnessing its rich resources and prioritizing environmentally friendly extraction methods, Canada has the potential to become a significant force in the global magnesium industry. This shift could not only propel the global transition to green energy but also bolster Canada’s economy in the process.

*Full disclosure: West High Yield Resources is an Equity Guru marketing client.