The Importance of Fertilizer

I am addicted to farming. To be more precise, I can’t seem to get enough of farming simulation video games, namely Stardew Valley. While a far cry from actual farming, this masterpiece of a game taught me that with the right fertilizer I could grow higher quality crops or even speed up the growing process. Pretty cool, right? Well, turns out this holds true in real life too, at least to some degree.

Sounds like a no-brainer, however, there’s a lot more to consider when it comes to fertilizer than you’d think. Unlike the lush field of Stardew Valley, nutrient management is crucial for farmers in order to increase or maintain crop yields on agricultural land. In order to meet crop needs throughout a growing season, soil fertility must be consistently high. With this in mind, there are 14 nutrients that are supplied to crops from soil and fertilizer sources.

Referring to the table above, six of these nutrients are considered macronutrients, including nitrogen, potassium, phosphorus, calcium, magnesium, and sulfur. In particular, nitrogen, phosphorus, and potassium are the three main nutrients typically supplied by inorganic fertilizers. That being said, while macronutrients are used in relatively larger amounts by crops, deficiencies in micronutrients can still be equally devastating to yield and profitability.

Ultimately, the nutrient requirement for each yield will vary depending on environmental factors such as soil type and weather conditions as well the nutrient being applied. For example, in California, roughly 40-50 lbs of nitrogen per acre or less is applied prior to or at the planting of carrots. On the other hand, something like alfalfa requires a starter application of 20-40 lbs of nitrogen per acre.

So, how do farmers manage nutrients in order to avoid deficiencies? As you probably could have guessed, the answer is fertilizer. To date, chemical fertilizers have been used to replace soil nutrients that are marginal or deficient in farm fields. In fact, it is estimated that fertilizer use has contributed to increased crop production in Western Canada by 50-60% annually. However, it’s not all good news.

Not So Fun Fertilizers

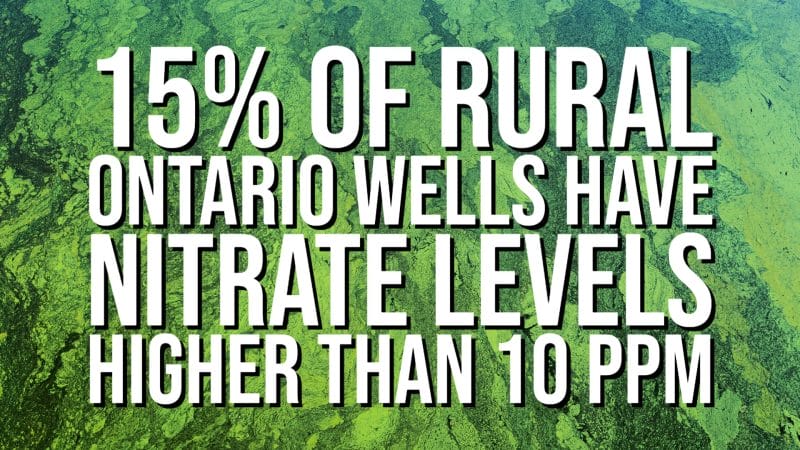

While nitrogen and phosphorus fertilizers generally have the greatest impact on crop yields, they have also been linked to negative environmental impacts. Under excess moisture conditions, nitrate from nitrogen fertilizer is able to leach into groundwater, causing contamination. According to the Ontario Water Standards (ODWS), the maximum allowable level of nitrate as nitrogen for drinking water in Ontario is set to 10 parts per million.

Any concentration of nitrate higher than this is considered toxic to humans and livestock. Additionally, recent research suggests that consistently high levels of nitrate in surface waters can harm some forms of aquatic life, particularly amphibians. With this in mind, studies published in scientific journals since the 1950s estimate that upwards of 15% of rural Ontario wells have nitrate levels greater than 10 parts per million.

Similar to nitrogen-based fertilizers, the heavy use of phosphorus fertilizers can cause major issues in lakes and streams. Let’s take a look at Lake Erie during the 1960s and 1970s. During this time, the impressive growth capabilities of phosphorus fertilizer were a double-edged sword. Ultimately, a combination of animal waste and fertilizer contributed to massive algae blooms, which essentially starved all other life in the lake of essential nutrients like oxygen. What’s the solution?

EarthRenew Inc.

- $19.773M Market Capitalization

EarthRenew Inc. (ERTH.C) manufactures high-value fertilizer from residues that build back productive, healthy soils critical to the high-growth regenerative agricultural market. In other words, the Company uses organic materials like food and animal byproducts to create regenerative fertilizer products. Unlike conventional nitrogen and phosphorus fertilizers, EarthRenew’s fertilizer products rebuild soil health and improve biodiversity without greenhouse gas (GHG) emissions or impacting water bodies.

Put simply, EarthRenew is a regenerative agriculture company. For context, regenerative agriculture refers to an alternative method of producing crops that carries lower, or potentially net positive, environmental impacts. At its core, regenerative agriculture aims to improve the health of soil or restore highly degraded soil, thereby improving water quality, vegetation, and land productivity.

Although the regenerative agriculture market is still in its infancy, there is a growing demand for regenerative fertilizer products, a niche that EarthRenew fits. In order to meet this demand, the Company plans to expand its production by building large-scale granulation facilities and establishing regional blending sites.

Currently, EarthRenew’s full-scale granulation facility in Beiseker, Alberta is capable of producing 16,000 metric tonnes (MT) per year of fertilizer. However, the facility is scaling up production to 20,000 MT of product annually. Furthermore, the Company’s DeBolt blending facility in Northern Alberta provides EarthRenew with distribution access to customers and distributors in the Grande Prairie and Peace Regions.

Replenish Nutrients Ltd.

Now that I have rambled on about regenerative agriculture, let’s talk about Replenish Nutrients Ltd., EarthRenew’s wholly-owned subsidiary responsible for manufacturing the Company’s brand of regenerative fertilizers. Conventional synthetic fertilizers provide nutrients to feed crops but offer no beneficial ecological outcomes. All take and no give; sound like my ex.

However, all Replenish Nutrients products are naturally sourced and designed to be applied using existing equipment, all the while delivering long-term benefits to the soil. In doing so, Replenish Nutrients is intended to increase productivity and reduce the number of chemicals required, such as pesticides. Moreover, regenerative fertilizers ensure that plants achieve optimal health by creating healthy, high-quality biologically active soil.

Referring back to EarthRenew’s manufacturing facilities, the Company’s production process uses traditional manufacturing equipment to blend and granulate regenerative products that can be used by standard farming equipment. Furthermore, EarthRenew’s production process enables the use of 100% of mined mineral sources, as opposed to just 30% for synthetic fertilizers.

It is also worth noting that the Company’s production process is non-chemical and has a significantly lower carbon footprint compared to traditional processes. In addition to manufacturing, on May 18, 2021, EarthRenew announced that it had entered into a Letter of Intent (LOI) with K+S Potash Canada (KSPC), a German-based company that has been mining and processing potash for over 125 years.

“Customers prefer our regenerative products because they are made from natural mineral sources which are essential to the plant but do not leach into groundwater like conventional products. KSPC’s potash is an integral part of our blends and this LOI further establishes our long-term relationship and commitment to building the best soil health products possible,” commented EarthRenew’s CEO, Keith Driver.

Potash refers to various mined and manufactured salts that contain potassium in water-soluble form. With this in mind, the LOI enables EarthRenew to lease approximately 15 acres of land from KSPC near the company’s existing Bethune, Saskatchewan potash mine and processing plant.

In doing so, EarthRenew intends to construct a new fertilizer manufacturing facility, which is projected to have the capacity to produce up to 200,000 tonnes of granulated regenerative and organic fertilizer product. Once produced, the Company expects to price these fertilizer products in the range of CAD$545 per MT, representing gross margins of 30%. In total, the construction of the facility is estimated to cost between $10-15 million.

Latest News

Most recently, on February 8, 2022, EarthRenew provided various updates to its stakeholders, reaffirming the Company’s promise to support farm systems focused on soil health. In particular, EarthRenew referenced positive results from a field trial evaluating the impact of the Company’s products on potatoes.

Outcomes of the trial included growing healthier potatoes at an equivalent marketable yield. Furthermore, compared to standard synthetic fertilizer, potato yields grown with EarthRenew’s products incurred lower overall program costs while improving the microbial diversity of the soil.

As for EarthRenew’s near-term facility in Bethune, the Company is quickly moving through the process required to fulfill its promise of building a 200,000 MT facility onsite at the KSPC potash mine. In addition to EarthRenew’s current and in development facilities, the Company is conducting feasibility studies for two additional sites, with one in the United States and the other in Canada.

As for EarthRenew’s financials, the Company’s reported revenue for the period January 2021 to December 2021 was $14 million, up 106% from the same period in 2020. Following the acquisition of Replenish Nutrients Ltd. on May 1, 2021, Replenish Nutrients reported $11.1 million in revenue.

Cumulatively, the total combined revenue of EarthRenew and Replenish Nutrients for the period January to December 2021, was $15.1 million. With this in mind, the Company is now focused on increasing capacity for the development of Replenish Nutrients’ products. Looking forward, EarthRenew’s projected revenue for the next year is expected to be in excess of $24 million.

If you’d like to know more about EarthRenew’s financials, you’ll have to check out Vishal’s article here! When it comes to EarthRenew, he’s our expert. Feel free to check out the video above for an exclusive Jody Vance interview with Keith Driver, EarthRenew’s CEO and Director.

Oh, and if you’re all for sustainability like I am, check out my Substack here!

EarthRenew’s share price opened at $0.24 matching a previous close of $0.24. The Company’s shares were trading at $0.24 at close on February 15, 2022.