On September 23, 2020 Defense Metals (DEFN.V) announced that it has received the final report from SGS Canada with respect to flotation pilot plant processing of its Wicheeda rare earth element (REE) property bulk sample at the SGS metallurgical test facility.

The news was positive – but before we get into it – let’s review the macro story:

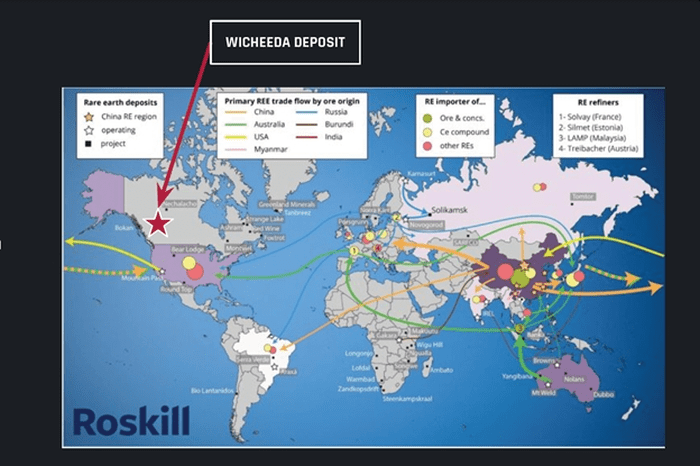

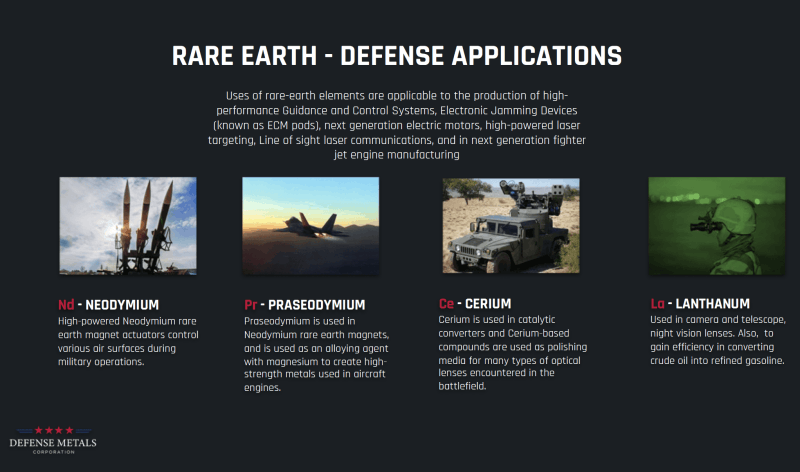

The U.S. is currently reliant on China for REEs – required for military applications such as jet engines, antimissile defence systems, satellites and lasers.

“REEs are also crucial for high-tech manufacturing,” confirms The Verge, “These elements are produced mostly in China, and used in the US for everything from electric cars to missiles”.

The U.S. currently gets 77% of its REEs from China.

The country is motivated to create friendly new non-China supply chains.

Three months ago, DEFN filed an updated 43-101 technical report on the 4,220 acre Wicheeda Rare Earth Element (REE) Property located near Prince George, British Columbia.

43-101 Technical Report Highlights:

- 49% increase in overall tonnage of Updated Wicheeda REE Project Mineral Resource Estimate (MRE) based on the results of 2019 diamond drilling of 13 holes totaling 2,007.5 metres;

- 30% increase in overall average grade, in part though the incorporation of potentially economically significant praseodymium not previously estimated;

- Conversion of 4,890,000 tonnes to Indicated Resources previously defined as Inferred;

- Increased Inferred Resources by 730,000 tonnes in comparison to Defense Metals Initial Wicheeda MRE; and

- Potential for expansion of the Wicheeda Deposit to the north and west in the down plunge direction.

Summary: the updated Wicheeda MRE comprises an Indicated Mineral Resource of 4.89 million tonnes averaging 3.02% LREO (Light Rare Earth Oxide), in addition to Inferred Mineral Resource of 12.1 million tonnes averaging 2.90% LREO reported at a cut-off grade of 1.5% LREE.

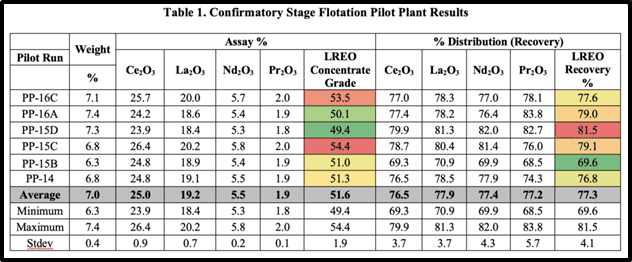

With respect to the results of the Wicheeda pilot plant, SGS stated: “The recent Wicheeda flotation pilot plant at SGS Lakefield resoundingly achieved its primary goals to validate the laboratory flowsheet at pilot plant scale, to provide data for engineering design and to generate high-grade REO concentrate.

Significant opportunities for improvement remain, including further investigation of the effects of reduced pulp temperature and reagent additions, which may provide opportunities for potential future process cost savings.

“The goals of the flotation pilot plant program were to validate the flowsheet developed during previous testwork on this deposit in 2019 at pilot plant scale,” stated DEFN, “to provide data for engineering design and to generate high-grade rare earth oxide (REO) concentrate”.

The completion of pilot plant testwork led to several important areas for further study that have the potential to improve metallurgical performance and reduce energy and reagent inputs leading to potential future process cost savings, including:

- Confirm the performance of the flotation circuit at lower pulp temperature (60 degrees Celsius);

- Further evaluate the effect of high-density conditioning, which can potentially provide significant cost savings on pulp heating.

Craig Taylor, CEO of Defense Metals, stated: “The success of the flotation pilot and 1,200 kilograms of high-grade REE concentrate produced, places Defense Metals and the Wicheeda REE deposit among rare company and opens the door to future hydrometallurgical pilot trials at SGS, with the ultimate goal of producing a Nd-Pr oxide product stream.”

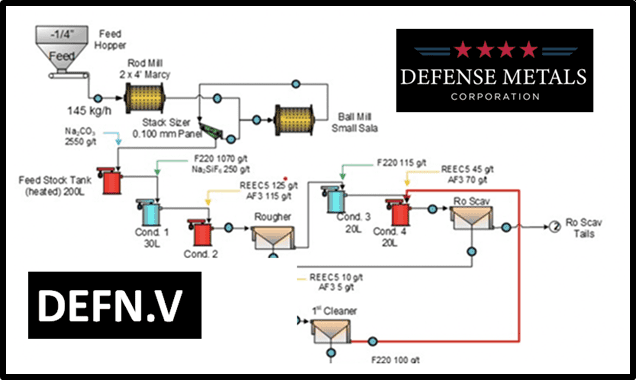

The Wicheeda flotation test charges were prepared by SGS from the 30-tonne Wicheeda sample which was crushed to nominal 12.7 millimetres (mm) using a combination of jaw and cone crushers.

The crushed material was homogenized using a front-end loader over a period of several hours.

Head grade and concentrate products for cerium, lanthanum, neodymium and praseodymium oxides were determined.

Defense Metals detected no significant QA/QC issues during review of the data.

A month ago, the Government of Saskatchewan announced $31 million in funding for a Rare Earth Element Processing Facility in that province. The facility will be owned and operated by the Saskatchewan Research Council (SRC).

The conversion of REE ore to individual REE products is done in two main stages.

The first is the concentration of ore to mixed REE Carbonate.

The second is the more complex separation stage that converts the mixed REE Carbonate to commercial pure-grade REEs.

The facility in Saskatchewan will address both stages of REE processing. The Saskatchewan Government believes that the global demand for REEs will increase significantly in the coming decade.

“Outside of China, the rest of the world is rapidly working to secure access to REE concentrate and processing facilities,” stated Taylor, “Given that the Wicheeda deposit is located in Canada, this gives us a strategic advantage as we continue to have discussions with various parties about this deposit.”

Let’s face it, without a PHD in metallurgy, the September 23, 2020 news is difficult to fully digest.

We do know DEFN has a high-grade REE asset (learn more about the geology in Greg Nolan’s August 16, 2020 EG article).

We also know that the metallurgy on this project will be critical to its economic prospects.

Today’s news pushes the project further along the development pipeline.

- Lukas Kane

Full Disclosure: Defense Metals is an Equity Guru marketing client.