What’s the first thing that comes to mind when you hear the word ‘brine’? Is it a sweet-salty slurry used to tenderize a carcass to impress your dinner guests? Always a nice touch. People will appreciate the result….

And people will speak highly to others of your culinary prowess…

There are other types of brines in this world – brines which transcend the individual appetite and palate. Just ask E3 Metals Corp (ETMC.V).

The company…

E3 is focused on brines in and around oil and gas reservoirs – brines containing potentially economic quantities of dissolved lithium.

This lithium is just sloshing around in waste water (petroleum brine), waiting to be extracted.

In case you weren’t aware…

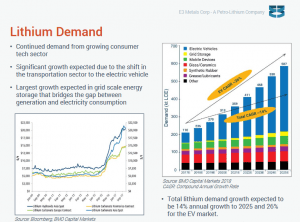

The demand for lithium continues to surge, primarily from consumer driven tech sectors.

Everything from EV’s (electric vehicles) to cell phone batteries require the soft, silvery-white alkali metal. Gone are the days of landlines. I gave mine up several years ago…

E3 is an interesting study in the evolution of a forward-thinking company that has discovered a unique resource and is pulling out all the stops to home in on the best ways to extract and concentrate it economically.

The E3 chronology…

The resource:

In the prolific Leduc Reservoir in Alberta, E3 Metals tabled a global inferred resource of some 6.7 million tonnes of LCE (lithium carbonate equivalent) at an average grade of 75 milligrams per litre.

Three separate resources have been defined to date.

- Clearwater – 1.9 million million tonnes of LCE.

- Rocky – .93 million tonnes of LCE.

- Exshaw West – 3.9 million tonnes of LCE.

The partnerships and gov’t funding sources…

14 operational collaborative partnerships with oil and gas companies bolster the resource end of the business.

The technology end of the biz has seen the company engage a number of strategic partnerships and funding sources, all with a goal of developing the most efficient lithium extraction and concentration process…

- E3 Metals Corp Signs Collaboration Agreement with the University of Alberta to Develop Technologies for Lithium Extraction – News link June 19, 2017…

- E3 Metals Receives Federal Government Grant for Expanded Lithium Extraction Technology Research with the University of Alberta – News link April 10, 2018…

- E3 Metals to collaborate with Scovan Engineering on scoping study for the development of its Alberta Petro-Lithium Project – News link June 20, 2018…

- E3 Metals awarded Government of Canada funding for advancement of lithium concentration technology – News link June 28, 2018…

- E3 Metals announces joint venture with Comstock Metals – News link August 8, 2018…

- E3 Metals granted $100,000 in funding from Alberta Innovates for the continued development of its lithium extraction technology – News link August 28, 2018…

Breakthroughs and milestones…

Developing an extraction and concentration process… this is a formidable challenge. This is where the rubber meets the road.

Substantially concentrating lithium at a grade of 75 milligrams per litre, and removing the majority of impurities along the way, is a tall order.

Pictured below is a simplistic view of what E3 is ultimately attempting to achieve…

E3 is up for the task…

The company already possesses a proprietary concentration technology, and earlier this summer, the company announced a breakthrough…

E3 Metals achieves fast & efficient concentration of lithium from its petro-lithium brine

Highlights…

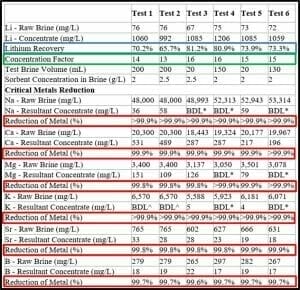

- Success in concentrating raw brine from 75 mg/L to 1206 mg/L Li in less than 3 hours.

- Concentration process removes over 99% of critical metal impurities.

- Lithium recoveries run as high as 81%.

Three hours and no evaporation time – zip, zero, nada – to generate a concentrate that can be purified with existing methodologies.

Though the lithium recovery rates were not what the company envisaged, falling 9% short of their 90% objective, this is all part of the tweaking process as they work to improve efficiencies and performance.

Solid progress. Super solid thinks this humble observer.

Another milestone…

Raising their game, just a few weeks back, the company began the process of scaling their laboratory test work…

E3 Metals Corp. Begins Development of a Field Pilot Plant to Test Its Rapid Lithium Extraction

It began with the development of a field pilot plant which will incorporate the company’s proprietary concentration technology to further validate its lithium extraction efficacy.

Again, this is where the rubber meets the road. This is where E3 will attempt to unlock value from their vast lithium resource base.

Pilot plant design and timeline…

As noted in the above news releases, E3 Metals has recently partnered with both GreenCentre Canada (GCC) and the National Research Council of Canada (NRC).

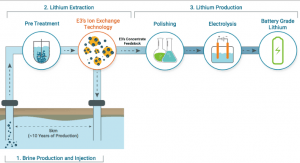

These partnerships are to advance E3’s ion-exchange technology developed by the Alessi Lab at the University of Alberta to commercial readiness. These facilities are working towards developing a commercially scalable lithium extraction process. The results of this work are expected to provide a commercial chemical sorbent. They will also determine the design parameters for the mechanical equipment required for the ion-exchange process that should provide all of the inputs required for the design of E3 Metals’ pilot plant.

The development plan for the next 6 months include:

- Demonstrating repeatability of the University of Alberta’s extraction technology development at commercial facilities (GCC and NRC).

- Increasing the performance efficiencies of the ion-exchange process by increasing recovery, concentration factor and lithium uptake.

- Developing a commercially scalable ion-exchange sorbent material.

- Constructing ion-exchange equipment in a lab environment to refine the mass balance and generate volumes of concentrate.

- Producing lithium hydroxide at the lab scale.

- Finalizing the lithium production process flow sheet.

- Finalizing the design of the pilot plant.

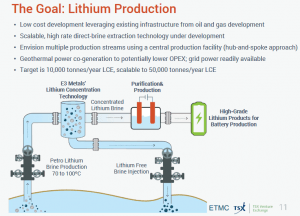

E3’s proposed lithium production flowsheet breaks down into three main steps.

- pump the lithium enriched brine from the Leduc reservoir to the surface.

- create a higher-grade lithium concentrate that utilizes E3’s proprietary ion-exchange process.

- generate a final lithium product (lithium hydroxide or carbonate) by further purification, electrolysis and crystallization.

Other development goals…

The planned operation of the pilot plant and the subsequent testing of E3’s concentrate feedstock in conventional lithium extraction process facilities at this scale will allow E3 to complete the front-end engineering design (FEED) for a process facility. During this time, E3 plans to upgrade a portion of its 6.7Mt (million tonne) Inferred resource to Measured and Indicated and complete a full cycle project economics analysis to pre-feasibility study (PFS) level. At this point, E3 intends to produce a compliant PFS 43-101 report outlining this information to the market.

Recent News…

The company already boasts a lithium resource so vast, it can rest on its laurels and never lift another finger on the exploration front.

This management team has other plans though.

E3 Metals Corp. Acquires Two Strategic MIM Permits in Alberta

HIGHLIGHTS…

Two new strategic Metallic and Industrial Minerals (MIM) permits bring E3’s total land position to over 590,000 hectares.

Historic sampling in the new area indicates lithium (Li) concentrations up to 120 mg/L2

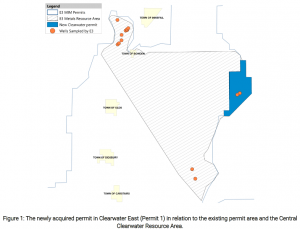

- The new Clearwater permit sits directly east of the existing Central Clearwater resource area (map below).

- Within this permit, historic sampling indicates lithium concentrations as high as 120 mg/L2.

- Recent sampling by E3 Metals confirmed lithium concentrations in the new Clearwater permit area ranging from 73 mg/L to 85 mg/L1.

- The new Exshaw permit is located directly east of the Exshaw West resource area (“Exshaw East”). Exshaw East connects E3 Metal’s permits to the Exshaw West project area.

Final thoughts…

The company is already sitting on one monster of a resource. Clearly, the company is not content sitting still.

This is a fast evolving story and I suspect newsflow will be strong on multiple fronts.

In this recent land acquisition news, the company stated…

The Clearwater East permit is a strategic acquisition for E3 Metals as it expands the highly prospective and original Clearwater area and provides an opportunity to revaluate the existing Clearwater Mineral Resource.

“… an opportunity to revaluate the existing resource” – that speaks volumes. It suggests management is busy looking at ways to unlock additional shareholder value.

This is one to watch.

END

~ ~ Dirk Diggler

Full disclosure: ETMC is an Equity Guru client. We own the stock.