Hydrogen Fuel: A Slippery Slope

Apparently, our last hydrogen article rustled some jimmies, so let’s clear the air. While that article focused on the value of hydrogen fuel, it did not consider today’s economic crisis. According to the United States (US) Department of Energy, as of January 2022, the national average retail fuel price of gasoline was USD$3.24 per gallon. This value is based on the submission of 1262 data points.

On the contrary, the average price of hydrogen was a lofty $16.69. However, it should be noted that this value is based on a much smaller sample of 17 data points. Even so, this value is in line with the average price per kilogram of hydrogen, which is between £10 and £15 in the United Kingdom (UK). Closer to home, the average price per kilogram of hydrogen was USD$16.51 in California back in 2019.

With this in mind, the price of hydrogen has not changed much over the years, at least not until recently. Following Russia’s invasion of Ukraine, the brent crude has surged to approximately $120 per barrel. As a result, the average price per gallon of gasoline in the US now sits at around $4.62, which is 52% higher than last year. Exacerbated by inflation, we likely won’t see gas prices drop anytime soon.

As a result, many have turned to fossil fuel alternatives like electric vehicles. In fact, according to TIME, a report found that 53% of active shoppers are considering more fuel-efficient vehicles in response to inflated gas prices. To be more specific, of 2,176 American automobile owners, 40% expect to own an electric vehicle in the next 5 years. So, what about hydrogen-powered vehicles?

Is Hydrogen Fuel Realistic?

According to JATO Dynamics, global sales of Hydrogen Fuel Cell Electric Vehicles (FCEV) totaled 15,500 units in 2021. In the same year, electric car sales more than doubled to 6.6 million, significantly overshadowing the FCEV market. However, while the market may be small, the demand for FCEVs increased by 84% when compared to sales in 2020. Against pre-pandemic levels, this translates to 103%.

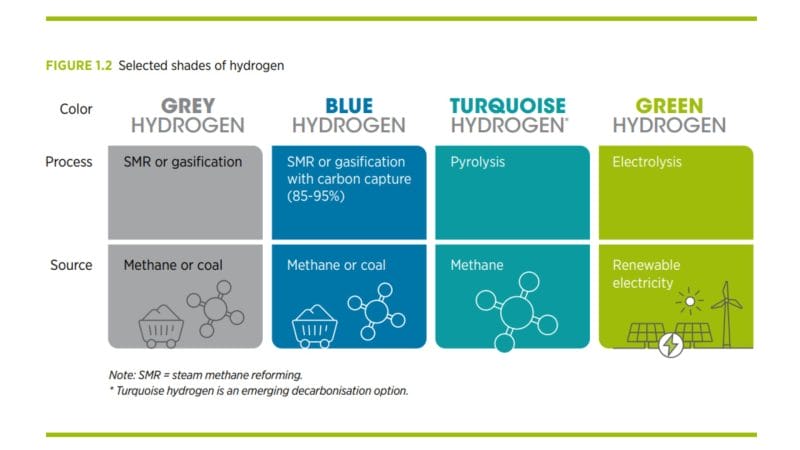

Before we move on, let’s first talk about the three primary types of hydrogen fuel, namely grey, blue, and green hydrogen. These colors are used to classify hydrogen fuel based on its production method; let’s start with grey hydrogen. Grey hydrogen is the most common form of hydrogen, largely because it is created from fossil fuels. It is primarily used in the chemical industry to create fertilizers.

The production of grey hydrogen relies on a process known as steam methane reforming (SMR). Put simply, SMR heats methane from natural gas with steam to create a mixture of hydrogen, carbon monoxide, and carbon dioxide. A process called pressure-swing adsorption (PSA) is then used to remove impurities like carbon dioxide from the gas stream, leaving pure hydrogen.

Similarly, SMR is also used to produce blue hydrogen. However, unlike grey hydrogen, a process referred to as Carbon Capture and Storage (CCS) is used to capture carbon dioxide at the production facility and store it separately, thereby significantly reducing emissions. With this in mind, blue hydrogen is typically seen as the cleaner hydrogen alternative when compared to grey hydrogen.

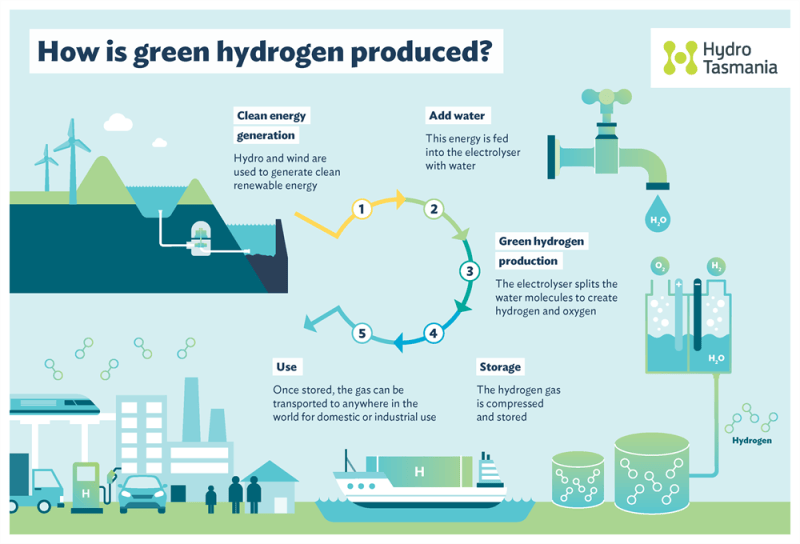

On the other hand, green hydrogen is the cream of the crop. While grey and blue hydrogen rely on SMR, green hydrogen is made using a process called electrolysis. In layman’s terms, electrolysis utilizes a mechanism called an electrolyzer to separate water into oxygen and hydrogen. Furthermore, green hydrogen relies on renewable energy sources like wind and solar energy.

The result is a closed-loop system that outputs zero harmful gasses, making it the most sustainable form of hydrogen fuel. It should be noted that there are other methods of hydrogen production, however, a majority of hydrogen is made using the SMR process. In fact, 95% of the world’s hydrogen was produced using the SMR process back in 2020. Why not electrolysis?

Limitations of Green Hydrogen

While green hydrogen is certainly sustainable, it is also quite pricey. According to the DOE, green hydrogen can be produced from polymer electrolyte membrane (PEM) electrolyzers at a cost of $5 to $6 per kilogram. Based on this information, green hydrogen would be more expensive than both grey and blue hydrogen. In the best-case scenario, green hydrogen is cost-competitive with blue hydrogen.

However, this data is from a 2020 report. Since then, our economy has plummeted while gas prices have skyrocketed. As a result, green hydrogen is actually cheaper than hydrogen produced from fossil fuels, namely grey hydrogen. In regions such as Africa, Europe, and the Middle East, grey hydrogen costs USD$6.71 per kilogram compared to USD$4.84 to USD$6.68 per kilogram for green hydrogen.

Rising gas prices aside, the cost of green hydrogen was always expected to see a price cut. By 2050, investments in hydrogen are estimated to reach $10 trillion. According to Rethink Energy, this will result in a 95% reduction in the cost of hydrogen. Furthermore, in areas with significant renewable energy resources, the cost of green hydrogen could drop to as low as USD$1.40 by 2030.

With this in mind, green hydrogen will either be on par or cheaper than blue hydrogen, which can be produced for under $2 per kilogram, by 2030. Be that as it may, the price of green hydrogen has already fallen below that of blue hydrogen in the Middle East.

While this is all great news, hydrogen is faced with one notable obstacle. Infrastructure. Even if green hydrogen was cheaper than traditional fossil fuels, the current hydrogen infrastructure does not support growth. At the end of 2021, there were only 685 hydrogen refueling stations in operation globally. Still, that’s an increase of approximately 26.85% from 540 stations worldwide in 2020.

North America possesses roughly 86 hydrogen refueling stations, 60 of which are located in California. On the contrary, in the same year, there were more than 1.1 million Electric Vehicle (EV) charging stations in China alone. Don’t get me wrong, I have nothing against hydrogen fuel, but it will be quite some time before hydrogen fuel infrastructure can compete with EVs, at least in North America.

The bottom line is that hydrogen fuel, particularly green hydrogen, looks very promising in the long term. In the short term, hydrogen will likely continue to be held back by the limitations of its infrastructure. Now, let’s take a look at a company that has already managed to reduce the cost of green hydrogen to as low as $1.50 per kilogram.

Hydrofuel Canada Inc. (Private)

First and foremost, it should be noted that Hydrofuel Canada Inc. is not publicly listed, however, the Company has stated that it intends to go public within a year at most. With that out of the way, let’s talk about what the Company offers. Hydrofuel is a Canadian-based company with subsidiaries in the US and Australia. The Company has developed various ammonia (NH3) fuel and energy technologies.

With this in mind, Hydrofuel has submitted 20 US Provisional Patent Applications for its ammonia fuel, electric power generation, and carbon capture technologies, among many others. According to Hydrofuel, the Company’s ammonia manufacturing process uses excess power generated by solar, wind, and utilities to create green ammonia. What does ammonia have to do with hydrogen?

The properties of ammonia are appealing for a variety of reasons. For starters, the physical composition of ammonia is similar to that of propane. This suggests that ammonia can be stored in a simple and cost-effective way. More importantly, 17.65% of ammonia is composed of hydrogen. Bearing this in mind, ammonia can be liquified to create a liquid with a volumetric hydrogen density 45% higher than liquid hydrogen.

Better yet, the byproduct of hydrogen made from ammonia is nitrogen, a non-toxic, non-greenhouse gas. Furthermore, ammonia-based hydrogen can be used directly in internal combustion engines (ICEs), a heat engine used in most gasoline and diesel vehicles. When burned in a traditional ICE, ammonia-based hydrogen produces no carbon emissions and can be used in both alkaline and non-alkaline fuel cells (FCs).

Referring back to Hydrofuel, the Company’s ammonia-based hydrogen contains 1.5 times more hydrogen than liquid hydrogen. In terms of monetization, Hydrofuel licenses its technology to institutions and companies under the Hydrofuel® trademark, which is registered in Canada, the US, and Europe.

Latest News

Last year, on March 31, 2021, Hydrofuel announced the closing of a non-brokered private placement of 2,000,000 units of the Company, priced at $0.65 per unit for gross proceeds of CAD$1,300,000. According to Hydrofuel, these proceeds were to be used to develop, license, and commercialize the Company’s proprietary ammonia energy and fuel production, storage, and utilization technologies.

Later in the year, on November 8, 2021, Hydrofuel announced that it would be acquiring Kontak, Hydrogen Storage LLC. In doing so, Hydrofuel now possesses Kontak’s patented reactor, which the Company acknowledges as the most effective method for releasing hydrogen for use in FCs and ICEs. At the same time, Hydrofuel announced a private placement offering of USD$5 million.

“$3 million of the proceeds will be dedicated for developing, commercialization, and licensing of Kontak’s technologies. The remaining balance will be used for the commercialization of Hydrofuel’s proprietary ammonia energy and fuel production, storage, and utilization technologies,” said Greg Vezina, Hydrofuel’s CEO.

Most recently, on April 25, 2022, Hydrofuel announced that it had completed an exclusive license agreement with the Georgia Institute of Technology for its patent-pending MAPS system. Georgia Tech’s Micro Ammonia Production System (MAPS) is capable of creating high yields of sustainable ammonia from air and water while boasting exceptional efficiency, sustainability, and simplicity.

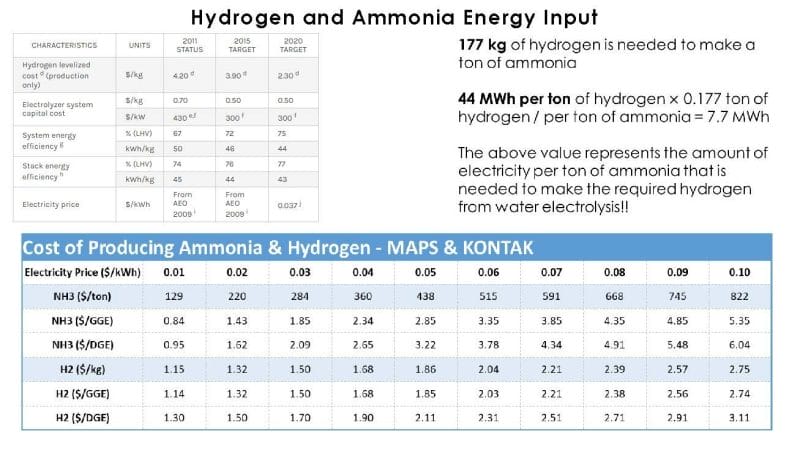

Combined with Kontak’s technologies, this will enable Hydrofuel to create green ammonia-based hydrogen using $0.02/kWh electricity for as little as $220 per tonne. To put things into perspective, fossil fuels derived from ammonia traditionally sell for between $1,500 and $2,000 per tonne. Green hydrogen can be separated from Hydrofuel’s ammonia and sold for as low as $1.50 per kilogram.

Will 2022 be a good year for hydrogen, or will the industry continue to be held back by a lack of infrastructure? If you would like to know more about hydrogen and FCEVs, check out our previous hydrogen article here. If you are more of a visual learner, check out today’s roundtable featuring three companies situated in the hydrogen industry.